Fa'aopoopo Fa'ameamea Fa'ameamea Pa'u u'amea 316l Pa'u mo le Lomitusi 3d

Fa'amatalaga o oloa

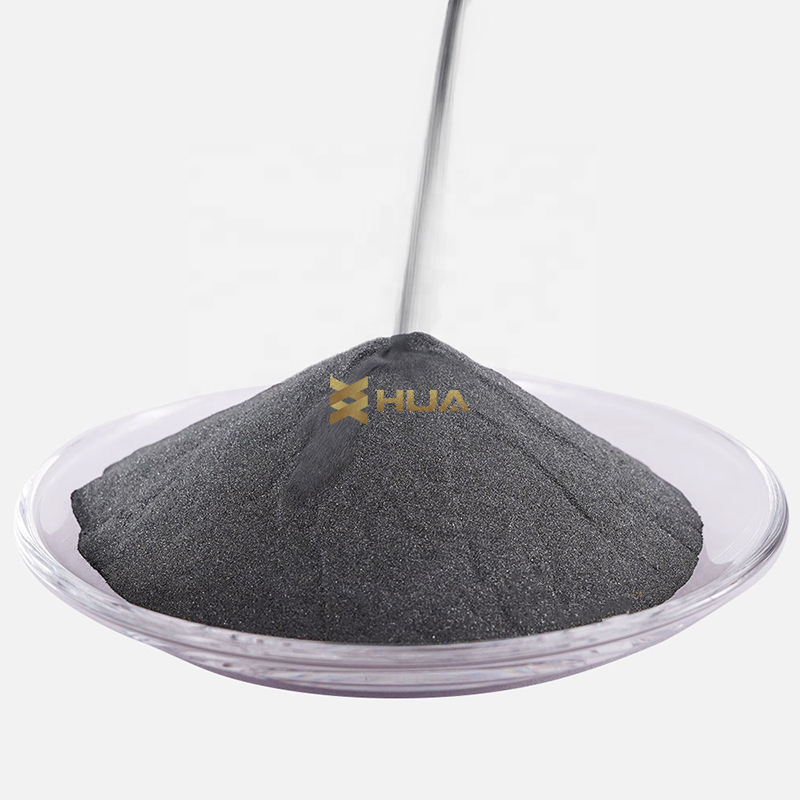

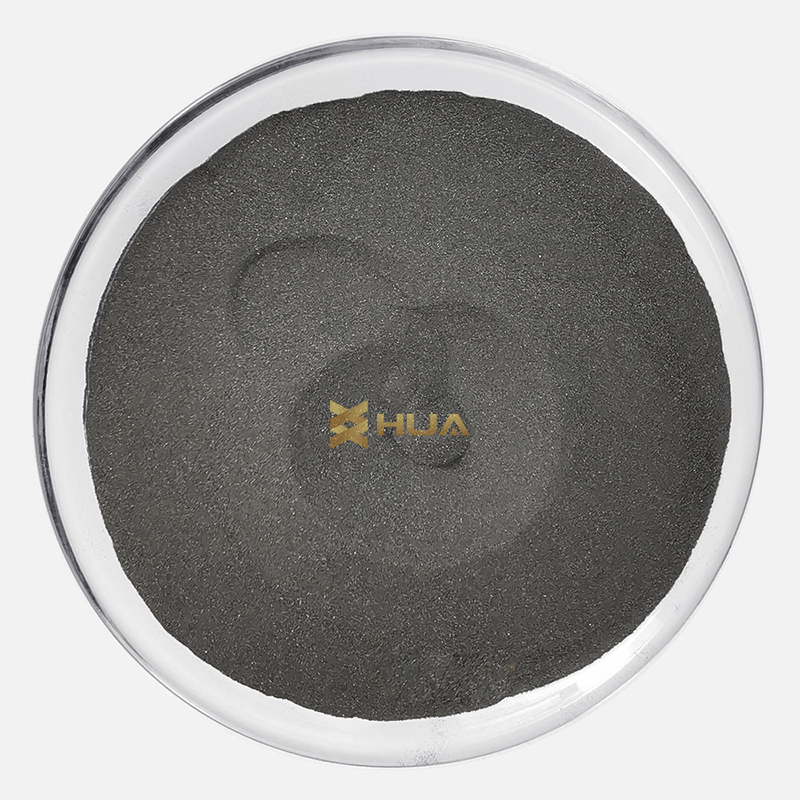

O le pauta u'amea uamea e faia i le vai atomization faagasologa ma e lelei le corrosion teteʻe ma tumau.O le pauta u'amea uamea e iai le tele o fa'aoga fa'apisinisi.

Tuuina atu ituaiga o pauta u'amea u'amea 'ese'ese lapopo'a.

E tusa ai ma le faʻaaogaina

1.Hot Isostatic Pressing

2.Metal Injection Molding

3.3D lolomi

4. Sulu vevela

E tusa ai ma le gaosiga o gaioiga

1.Atomization vai

2.Water kasa tuufaatasia atomization

3.Gas atomization

4.Atomization gaogao

Fa'amatalaga fa'amatalaga

| Fa'atosina pa'u uamea % | |||||||||

| Vasega | Cr | Ni | Mo | Nb | Cu | S | P | C | Si |

| 303 | 17-19 | 8-13 |

|

|

| 0.15-0.3 | ≤0.2 | ≤0.15 | ≤1 |

| 304 | 18-20 | 8-12 |

|

|

| ≤0.03 | ≤0.04 | ≤0.08 | ≤1 |

| 316 | 16-18 | 10-14 | 2-3 |

|

| ≤0.03 | ≤0.04 | ≤0.08 | ≤1 |

| 303L | 17-19 | 8-13 |

|

|

| 0.15-0.3 | ≤0.2 | ≤0.03 | ≤1 |

| 304L | 18-20 | 8-12 |

|

|

| ≤0.03 | ≤0.04 | ≤0.03 | ≤1 |

| 316L | 16-18 | 10-14 |

|

|

| ≤0.03 | ≤0.04 | ≤0.03 | ≤1 |

| 317L | 18-21 | 12-16 | 3-4 |

|

| ≤0.03 | ≤0.04 | ≤0.03 | ≤1 |

| 314 | 24-27 | 18-21 |

|

|

| ≤0.03 | ≤0.04 | ≤0.2 | 1.5/2.5 |

| 310 | 24-26 | 19-22 |

|

|

| ≤0.03 | ≤0.04 | ≤0.08 | ≤1 |

| 303LSC | 17-19 | 8-13 |

|

| 2 | 0.15-0.3 | ≤0.2 | ≤0.03 | ≤1 |

| 304LSC | 17-19 | 8-13 |

|

| 2 | ≤0.03 | ≤0.04 | ≤0.03 | ≤1 |

| 316LSC | 16-19 | 10-14 | 2-3 |

| 2 | ≤0.03 | ≤0.04 | ≤0.03 | ≤1 |

| 410L | 11.5-13.5 |

|

|

|

| ≤0.03 | ≤0.04 | ≤0.03 | ≤1 |

| 430L | 16-18 |

|

|

|

| ≤0.03 | ≤0.04 | ≤0.03 | ≤1 |

| 434L | 16-18 |

| 0.75-1.25 |

|

| ≤0.03 | ≤0.04 | ≤0.08 | ≤1 |

| 434LNB | 16-18 |

| 0.75-1.25 | 0.4-0.6 |

| ≤0.03 | ≤0.04 | ≤0.03 | ≤1 |

| 410 | 11.5-13.5 |

|

|

|

| ≤0.03 | ≤0.04 | ≤0.25 | ≤1 |

| 420 | 12-14 |

|

|

|

| ≤0.03 | ≤0.04 | 0.25/0.35 | ≤1 |

| 430 | 16-18 |

|

|

|

| ≤0.03 | ≤0.04 | ≤0.08 | ≤1 |

| 434 | 16-18 |

| 0.75-1.25 |

|

| ≤0.03 | ≤0.04 | ≤0.08 | ≤1 |

| 440 | 16-18 |

|

|

|

| ≤0.03 | ≤0.04 | 0.9/1.2 | ≤1 |

| 17-4PH | 15-17.5 | 3-5 |

| 0.15-0.456 | 3-5 | ≤0.03 | ≤0.04 | ≤0.07 | ≤1 |

| 15-5PH | 14-15.5 | 3.5-5.5 |

|

| 2.5-4.5 | ≤0.03 | ≤0.04 | <=0.07 | ≤1 |

Fa'aaogāga

E mafai ona fa'aogaina le pauta u'amea fa'afefete mo le fa'afefeteina o le vevela, pa'u pa'u pa'u, pa'u u'amea lolomi lolomi sintering (PM), tui tui (MIM) sintering faamama, ma isi, vai atomization okesene mea.<4000PPM, fa'atosinaga kasa<1000PPM.

Tulaga lelei ole pauta u'amea u'amea HUARUI

●E oo lava i le tuufaatasiga o le paʻu, faʻaitiitia mea leaga

●Sphericity maualuga

●E maualalo le okesene i totonu

● lelei flowability

●Mata'aese le mamafa, maualuga tap density

●Le itiiti ifo le paʻu omo, itiiti satelite pauta

Faiga pulea lelei

1.Huarui o loʻo i ai faiga faʻapitoa tau pulega lelei.Matou te suʻesuʻeina muamua a matou oloa pe a maeʻa a matou gaosiga, ma matou toe faʻataʻitaʻi aʻo leʻi tuʻuina atu uma, e oʻo lava i faʻataʻitaʻiga.Ma afai e te manaʻomia, matou te manaʻo e talia isi vaega e suʻe.Ioe pe afai e te fiafia i ai, e mafai ona matou tuʻuina atu faʻataʻitaʻiga ia oe e suʻe ai.

2.O matou oloa lelei e faʻamaonia e Sichuan Metallurgical Institute ma Guangzhou Institute of Metal Research.O le galulue faʻatasi ma i latou e mafai ona faʻasaoina le tele o taimi suʻega mo tagata faʻatau.